Carbon dioxide (CO2) lasers, renowned for their diverse applications across industries, derive their efficacy from a meticulous construction and a fundamental working principle. This article delves into the intricacies of CO2 laser design and operation, elucidating the components involved and the principles that govern their functionality.

Construction of CO2 Lasers:

Gas Reservoir:

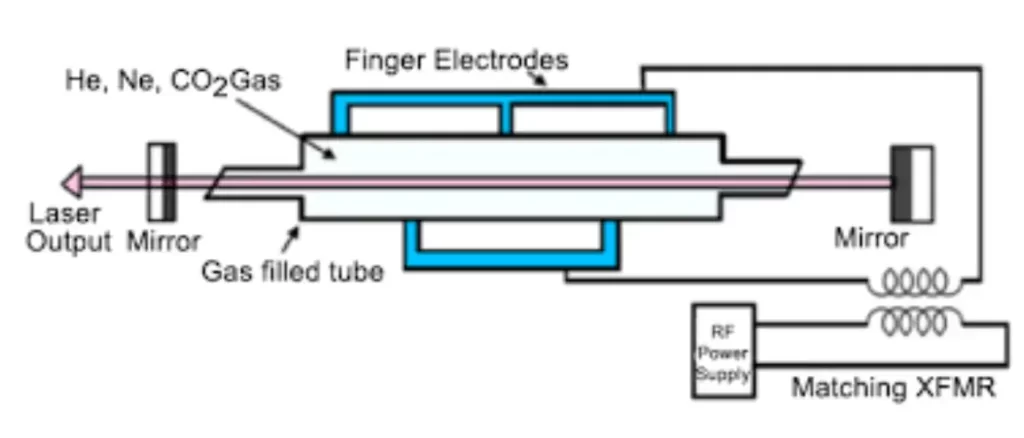

The heart of a CO2 laser system lies in its gas mixture. Typically composed of carbon dioxide (CO2), nitrogen (N2), and helium (He), the gas reservoir ensures a controlled environment for laser action.

The proportions of each gas in the mixture are carefully calibrated, with CO2 being the primary lasing medium.

Electrical Discharge System:

CO2 lasers rely on an electrical discharge to excite the gas mixture and create a population inversion—a condition where more molecules are in higher energy states than lower ones.

Two common methods for inducing the electrical discharge are radio-frequency (RF) excitation or direct current (DC) discharge.

Optical Cavity:

The laser cavity consists of two mirrors, one highly reflective and the other partially transmissive.

The mirrors define the optical path and facilitate the creation of a standing wave pattern that enhances the amplification of the laser light.

Laser Tube:

The laser tube, housing the gas mixture, is a critical component. It is designed to withstand the pressure created during the discharge and to maintain a stable environment for the laser action.

Cooling System:

Due to the heat generated during the laser process, an efficient cooling system is essential. Water or gas-based cooling systems help maintain the temperature within the laser tube, preventing overheating and ensuring stable performance.

Working Principle of CO2 Lasers:

Population Inversion:

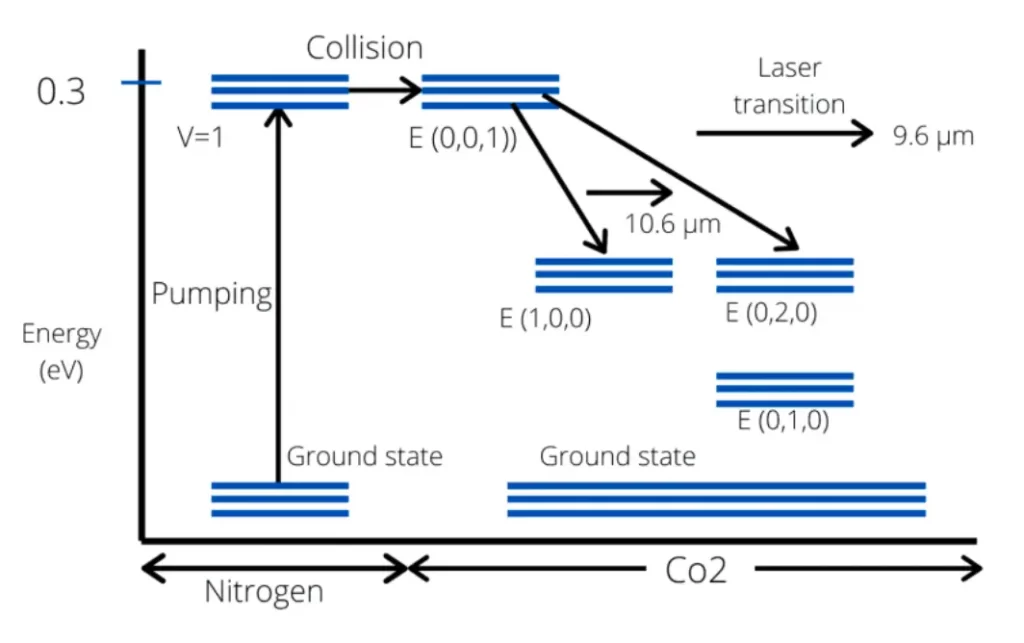

The working principle of CO2 lasers hinges on achieving population inversion within the gas mixture. The electrical discharge excites the CO2 molecules to higher energy states, creating a surplus of high-energy particles.

Stimulated Emission:

Stimulated emission occurs when a high-energy CO2 molecule collides with another excited CO2 molecule. This collision induces the emission of a photon, resulting in the amplification of light.

Mirror Reflections:

The amplified photons travel back and forth between the mirrors within the optical cavity. This causes the stimulated emission process to continue, leading to further amplification.

Emission of Laser Beam:

The partially transmissive mirror allows a fraction of the amplified photons to pass through, resulting in the emission of a coherent, high-intensity laser beam.

Wavelength and Infrared Emission:

CO2 lasers emit light at a wavelength of approximately 10.6 micrometers, falling within the mid-infrared region. This wavelength is crucial for the laser’s effectiveness in various applications, such as cutting, welding, and medical procedures.

Conclusion:

The construction and working principle of CO2 lasers exemplify a synergy between precision engineering and fundamental physics. As advancements in materials and technology continue, the efficiency and versatility of CO2 lasers are poised to reach new heights, solidifying their role as indispensable tools across a myriad of industries. Understanding the intricacies of CO2 laser systems paves the way for further innovations and applications in the ever-evolving landscape of laser technology.