In the world of materials science, the terms crystallite size and particle size are often used interchangeably, but they refer to distinct properties of materials. Both are crucial for understanding the behaviour and characteristics of materials at the microscopic level. This blog will delve deeply into the definitions, differences, significance, and examples of crystallite size and particle size, providing a comprehensive understanding of both concepts.

1. What is Crystallite Size?

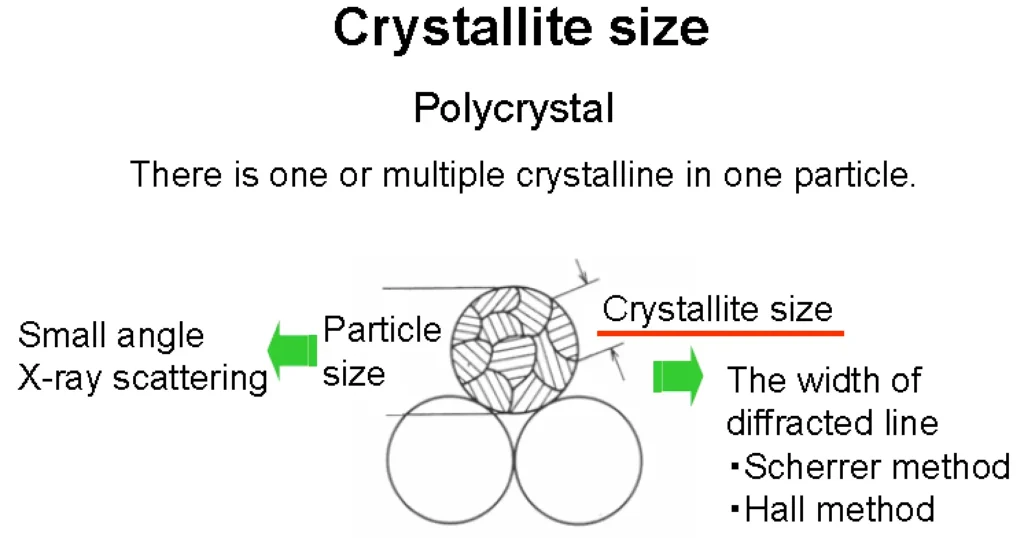

Crystallite size refers to the size of a single crystal or a small region of a crystalline material where atoms or molecules are arranged in an orderly, repeating pattern. Even in a material that is polycrystalline (composed of many small crystals), the crystallites are often not visible to the naked eye and require specialized techniques for their measurement. Crystallite size is indicative of the scale at which crystalline order exists within the material.

- Crystallites vs. Crystals: It’s essential to distinguish between crystallites and crystals. A crystallite is a very small region of a crystal, and multiple crystallites together make up a larger crystal. A large crystal may contain several crystallites, each with its own distinct lattice orientation.

- Measurement of Crystallite Size: Crystallite size is usually measured through X-ray diffraction (XRD), where the broadening of diffraction peaks provides insight into the average crystallite size. Other techniques like electron microscopy and atomic force microscopy (AFM) can also be used to measure crystallites.

Example of Crystallite Size: Consider a material like graphite. When graphite is synthesized in a laboratory, the crystallite size can range from nanometres (in nanoparticle graphite) to several micrometres (in larger crystalline forms). The smaller the crystallite size, the larger the surface area of the material, which impacts properties such as electrical conductivity, catalytic activity, and mechanical strength.

2. What is Particle Size?

Particle size refers to the dimensions of an individual particle in a material. Particles may or may not be crystalline and can include both solid and non-solid phases like liquids and gases. Particle size is crucial when studying powders, granules, and particulate materials, where the size of individual particles plays a significant role in determining the material’s properties and behaviours.

- Measurement of Particle Size: Particle size is measured using techniques like laser diffraction, dynamic light scattering (DLS), and scanning electron microscopy (SEM). Particle size distribution (PSD) is also often analysed, which represents the distribution of particles by size within a sample.

- Difference from Crystallite Size: While crystallite size refers to the size of individual crystalline regions, particle size measures the overall dimensions of a particle, which can include multiple crystallites. The particle may contain many crystallites, and the particle’s size can vary significantly, even if the crystallites themselves are of similar size.

Example of Particle Size: In the pharmaceutical industry, the particle size of a drug powder directly affects its bioavailability. A drug with smaller particle sizes has a greater surface area for interaction with solvents, leading to faster dissolution rates and improved absorption in the body. For instance, aspirin in the form of nanoparticles can be absorbed more rapidly than larger tablet forms.

3. Key Differences Between Crystallite Size and Particle Size

Though both crystallite size and particle size are related to the size of material components, they differ fundamentally in terms of what they measure:

Property | Crystallite Size | Particle Size |

|---|---|---|

Definition | Size of individual crystalline regions within a material. | Size of individual particles, which may contain many crystallites. |

Scope | Focuses on atomic or molecular arrangement. | Focuses on the overall dimensions of particles (which may be crystalline or non-crystalline). |

Measurement | Typically measured using X-ray diffraction (XRD), electron microscopy, or AFM. | Measured using techniques like laser diffraction, dynamic light scattering, or SEM. |

Impact | Affects properties like crystallinity, strength, and conductivity. | Affects properties like flowability, dissolution rate, and stability. |

Applications | Important in materials science, catalysis, and nanotechnology. | Critical in industries like pharmaceuticals, cosmetics, and food production. |

4. Why Do Crystallite Size and Particle Size Matter?

Both crystallite size and particle size have significant impacts on the physical, chemical, and mechanical properties of materials. Understanding these sizes is essential in tailoring materials for specific applications.

Influence of Crystallite Size:

- Mechanical Properties: Smaller crystallites lead to greater grain boundaries, which can impede the movement of dislocations and enhance the material’s strength. This is why nanocrystalline materials, with smaller crystallites, tend to have superior mechanical properties like hardness.

- Electrical and Thermal Conductivity: The smaller the crystallites, the higher the resistance to electron or heat flow due to the increased number of grain boundaries that scatter carriers.

- Catalysis: Catalysts often perform better when they have a higher surface area-to-volume ratio. Smaller crystallites expose more surface atoms, making them more reactive. For example, platinum nanoparticles are often used as catalysts in automotive catalytic converters.

Influence of Particle Size:

- Dissolution Rate and Absorption: Smaller particles have a larger surface area, which means they dissolve faster. In the pharmaceutical industry, this principle is applied to enhance the bioavailability of drugs. Smaller particles are also more easily absorbed by the body.

- Flowability: In industries like powder metallurgy or cosmetics, particle size can influence the flowability of powders. Finer powders tend to have poorer flowability due to cohesion between particles, while coarser powders flow more easily.

- Material Properties: In pigments, cosmetics, or coatings, the particle size can determine the appearance of the product. Smaller particles are often used for smoother textures or finer finishes.

5. Applications in Different Industries

- Nanotechnology: Nanotechnology heavily relies on materials with small crystallite and particle sizes. Nanomaterials, which have crystallite sizes typically in the range of 1-100 nanometres, exhibit unique properties like increased strength, high chemical reactivity, and high electrical conductivity. For example, carbon nanotubes, with a crystallite size on the nanoscale, have applications in electronics, energy storage, and drug delivery.

- Pharmaceuticals: As previously mentioned, particle size plays a crucial role in determining the solubility and bioavailability of drugs. In formulations like inhalers, fine particles ensure that the drug reaches the lungs effectively. Similarly, the crystallite size of active pharmaceutical ingredients (APIs) affects their solubility and stability in a drug formulation.

- Cement Industry: In cement, the particle size of the raw material and the crystallite size of the clinker phase play an important role in determining the setting time and final strength of the concrete. Smaller particles allow for better hydration, which improves the performance of the cement.

- Electronics: In the production of semiconductors, both crystallite and particle sizes are important. Smaller crystallites can help improve conductivity in certain materials, while control over particle size ensures uniformity in the manufacturing process of components like transistors or solar cells.

Conclusion

While crystallite size and particle size are related, they describe different aspects of a material. Crystallite size focuses on the internal order of the material at the atomic level, while particle size is concerned with the overall dimensions of the material’s individual particles. Both play a significant role in determining the properties and applications of materials across various industries. Whether you’re designing a more efficient drug formulation, enhancing the strength of a metal alloy, or developing a new semiconductor material, understanding and controlling both crystallite and particle sizes is crucial to achieving desired material performance.