Grain boundaries are fundamental concepts in materials science and metallurgy that play a crucial role in determining the properties of materials. These boundaries, which form the interfaces between individual crystalline regions or “grains,” significantly influence the behaviour of metals, ceramics, and other crystalline solids. In this blog, we will explore what grain boundaries are, their types, their effects on material properties, and their applications in various fields.

What Are Grain Boundaries?

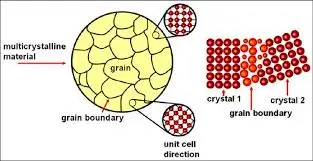

In crystalline materials, atoms are arranged in a highly ordered, repeating structure, forming a lattice. A “grain” refers to a single crystal within a material, and each grain has a well-defined orientation of this atomic lattice. Grains in a material are separated by regions called grain boundaries, where there is a misalignment or mismatch in the atomic arrangement between adjacent grains.

Grain boundaries can be thought of as “defects” in the crystal structure since they disrupt the perfect periodic arrangement of atoms. The orientation difference between adjacent grains can vary, leading to different types of grain boundaries.

Formation of Grain Boundaries

Grain boundaries are formed during the solidification or cooling process of a material. As the material cools, crystals begin to form and grow. When two crystals meet, they align in such a way that a grain boundary is created between them. In polycrystalline materials (materials made up of many grains), grain boundaries are abundant and vary in orientation, energy, and structure.

Types of Grain Boundaries

Grain boundaries are classified based on their orientation relationship between adjacent grains. Some of the key types of grain boundaries are:

1. Low-Angle Grain Boundaries (LAGBs)

Low-angle grain boundaries occur when the misalignment between adjacent grains is small. The grains are nearly aligned, with a misorientation angle typically less than 10°. These boundaries are characterized by an array of dislocations (defects in the crystal structure) that help accommodate the misalignment.

- Characteristics: Low-angle grain boundaries are relatively “soft” and contribute less to material strength. They are more mobile and less resistant to deformation.

2. High-Angle Grain Boundaries (HAGBs)

High-angle grain boundaries have a significant misorientation between adjacent grains, typically greater than 10°. This results in more pronounced dislocations and a higher degree of misalignment in the crystal lattice.

- Characteristics: High-angle grain boundaries are usually more resistant to deformation than low-angle boundaries. They can act as barriers to the movement of dislocations, which increases the strength and hardness of the material.

3. Tilt Grain Boundaries

Tilt grain boundaries occur when adjacent grains are misoriented along an axis perpendicular to the boundary. The grains are rotated around an axis parallel to the grain boundary, creating a tilt.

- Characteristics: Tilt boundaries can be either low-angle or high-angle, depending on the degree of misorientation between the grains. These boundaries have a specific geometric arrangement that can influence the material’s properties.

4. Twist Grain Boundaries

Twist grain boundaries are created when adjacent grains are rotated around an axis parallel to the boundary. These boundaries usually result in a twist or spiral-like structure at the interface.

- Characteristics: Twist grain boundaries can be seen in crystals where there is a rotational misalignment between the grains. They can often be more complex than tilt boundaries.

5. Coincidence Site Lattice (CSL) Boundaries

Coincidence site lattice boundaries are a special class of high-angle grain boundaries where the lattice points of adjacent grains align periodically. These boundaries are characterized by a specific, repeating pattern of misalignment that minimizes the energy of the boundary.

- Characteristics: CSL boundaries often have lower energy than random high-angle grain boundaries and may exhibit enhanced material properties such as increased resistance to corrosion or improved strength.

Significance of Grain Boundaries in Material Properties

Grain boundaries play a key role in determining the mechanical, thermal, and electrical properties of materials. Their effects can be both beneficial and detrimental depending on the material and application.

1. Mechanical Properties

The mechanical behaviour of a material, including its strength, toughness, and ductility, is significantly influenced by grain boundaries. Here are some ways in which grain boundaries affect mechanical properties:

- Strengthening Mechanism (Hall-Petch Effect): As the grain size decreases, the number of grain boundaries increases, which can impede the motion of dislocations. This phenomenon is known as the Hall-Petch effect, which states that materials with smaller grains tend to be stronger, as grain boundaries act as barriers to dislocation movement. Smaller grains lead to higher strength and hardness but may reduce ductility.

- Fracture Toughness: Grain boundaries can influence the fracture toughness of materials. In some cases, grain boundaries may act as sites for crack initiation, leading to brittle fracture. In other cases, grain boundaries may act as a toughening mechanism by deflecting or absorbing cracks.

- Grain Boundary Sliding: During high-temperature deformation, grain boundaries can experience sliding, which can lead to creep (slow deformation under stress). This process is particularly relevant in materials used in high-temperature applications, such as turbine blades.

2. Thermal and Electrical Conductivity

Grain boundaries disrupt the flow of electrons and phonons (heat carriers) through a material. This makes grain boundaries influential in the thermal and electrical conductivity of materials.

- Thermal Conductivity: Grain boundaries can scatter phonons, reducing the thermal conductivity of the material. This can be beneficial in applications requiring thermal insulation but may be undesirable in materials used for heat dissipation (e.g., heat exchangers).

- Electrical Conductivity: Grain boundaries can act as barriers to electron flow, reducing the material’s electrical conductivity. This is particularly important in semiconductor materials where controlling electrical conductivity is crucial.

3. Corrosion Resistance

Grain boundaries are often sites for the accumulation of impurities and defects, which can make them more susceptible to corrosion. In materials such as stainless steel, grain boundary corrosion (also known as intergranular corrosion) can occur when certain elements (e.g., chromium) become depleted along the grain boundaries, leading to localized corrosion. In contrast, the presence of certain grain boundary structures (such as CSL boundaries) can improve corrosion resistance.

4. Magnetic Properties

Grain boundaries can influence the magnetic properties of materials. For instance, in ferromagnetic materials, grain boundaries can alter the alignment of magnetic domains, affecting the material’s magnetic behaviour. Grain boundary engineering can be used to optimize magnetic properties for specific applications, such as in permanent magnets or magnetic sensors.

Grain Boundary Engineering

Grain boundary engineering refers to the process of manipulating the structure and distribution of grain boundaries to enhance the properties of materials. By controlling factors such as grain size, boundary orientation, and the presence of specific grain boundary types (e.g., CSL boundaries), it is possible to tailor material properties for specific applications.

Some methods of grain boundary engineering include:

- Thermal and Mechanical Treatments: Techniques like annealing, cold working, and hot isostatic pressing can be used to modify the microstructure and grain boundary characteristics of materials.

- Alloying: The addition of specific alloying elements can promote the formation of favourable grain boundary structures, improving strength, ductility, and resistance to corrosion.

- Grain Boundary Control in Thin Films: In applications such as microelectronics and nanomaterials, grain boundary control is crucial for improving the performance of thin films and nanostructures.

Applications of Grain Boundaries

Grain boundaries have diverse applications across various industries. Some notable examples include:

1. Metallic Alloys

In materials like steel, aluminium, and titanium alloys, grain boundaries are crucial in determining the strength and performance of the material. The Hall-Petch effect is commonly exploited to enhance the strength of alloys, while grain boundary engineering is used to improve properties like toughness and fatigue resistance.

2. Semiconductors

In semiconductor materials, grain boundaries can have a significant impact on electrical conductivity and electronic behaviour. Engineers manipulate grain boundary characteristics in the fabrication of devices like transistors, diodes, and solar cells to optimize performance.

3. Energy Materials

Grain boundaries are critical in energy storage and conversion materials, such as batteries, fuel cells, and thermoelectric. In these applications, grain boundaries affect ionic conductivity, charge transport, and overall efficiency.

4. Nanomaterials

Nanomaterials, due to their small grain sizes, exhibit unique properties that are strongly influenced by grain boundary behaviour. Researchers in nanotechnology often focus on controlling grain boundary structures to improve material properties such as strength, conductivity, and stability.

5. Ceramics and Composites

In ceramics and composite materials, grain boundaries play a key role in determining toughness, thermal stability, and resistance to wear. For instance, in high-performance ceramics used in aerospace or electronics, grain boundaries are engineered to enhance durability and heat resistance.

Conclusion

Grain boundaries are a vital aspect of material science, influencing the mechanical, thermal, and electrical properties of materials. Their complex behaviour, including the type, orientation, and energy of grain boundaries, can have significant implications for the performance and application of materials. With advances in grain boundary engineering, it is possible to tailor materials for specific uses, enhancing their strength, durability, and overall functionality. As research continues to evolve, our understanding of grain boundaries will unlock new possibilities for creating advanced materials with enhanced performance in various industries.