X-ray diffraction (XRD) is a powerful and widely used technique in materials science for characterizing the structural properties of materials at the atomic or molecular level. It provides detailed information about the crystal structure, phase identification, texture, and other material properties. XRD works by directing X-rays at a material and measuring the diffraction pattern produced as the X-rays interact with the atomic planes within the crystal lattice.

This method is commonly applied in the analysis of metals, polymers, ceramics, semiconductors, and minerals, among others. XRD is indispensable in the fields of materials science, chemistry, geology, physics, and engineering.

In this blog, we will delve into the various aspects of XRD material characterization and how it is used to analyze materials effectively.

How XRD Works: The Basics

The fundamental principle behind X-ray diffraction involves the interaction of X-rays with the periodic arrangement of atoms within a crystalline material. When a monochromatic X-ray beam hits a crystal, the atoms cause the X-rays to scatter in specific directions, producing a diffraction pattern. This pattern can then be analyzed to extract valuable information about the material’s structural properties.

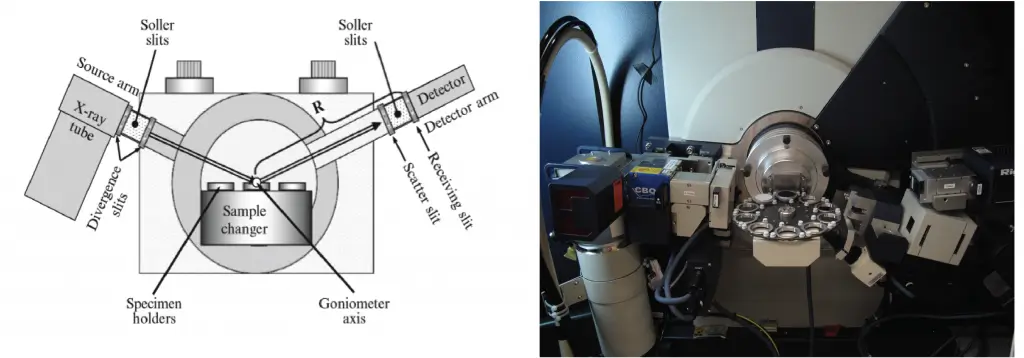

The key components involved in XRD are:

- X-ray Source: A tube or synchrotron radiation source generates X-rays with a specific wavelength.

- Sample Holder: The material to be analyzed is placed on a holder.

- Detector: The diffracted X-rays are detected and recorded, typically by an array of detectors.

- Goniometer: This mechanism rotates the sample or the detector to different angles to collect the diffraction data.

The Diffraction Equation

The relationship that governs the diffraction pattern is known as Bragg’s Law:

nλ=2dsin(θ)n\lambda = 2d\sin(\theta)nλ=2dsin(θ)

Where:

- nnn is the order of reflection (usually 1),

- λ\lambdaλ is the wavelength of the X-rays,

- ddd is the distance between crystal planes,

- θ\thetaθ is the angle of incidence (Bragg angle).

Bragg’s Law explains how X-rays with specific wavelengths are diffracted by the crystal lattice, producing peaks in the diffraction pattern that correspond to specific planes within the crystal structure.

Types of XRD Techniques

XRD is a versatile technique that can be applied in different configurations depending on the material being analyzed and the information needed. Some of the main types of XRD techniques include:

1. Powder X-ray Diffraction (PXRD)

Powder XRD is the most common method used for phase identification and structural analysis. In this method, the sample is ground into a fine powder, which ensures that many different crystal orientations are sampled simultaneously. As the sample is rotated in the X-ray beam, a diffraction pattern is collected, which can then be compared to standard diffraction patterns from databases such as the International Centre for Diffraction Data (ICDD).

Applications:

- Phase identification in crystalline materials.

- Quantitative analysis of phase mixtures.

- Determination of crystal structure.

2. Single-Crystal X-ray Diffraction

In single-crystal XRD, a single, large crystal of the material is analyzed. This technique provides more detailed information than powder diffraction because it enables precise determination of the atomic positions within the crystal lattice.

Applications:

- Determining the full three-dimensional crystal structure of small molecules or complex materials.

- Detailed analysis of bond lengths, bond angles, and atomic coordination.

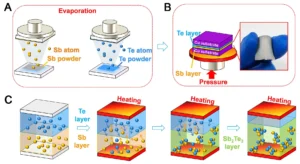

3. High-Resolution X-ray Diffraction (HRXRD)

HRXRD is employed for the analysis of thin films and layered materials. It provides high precision in measuring lattice spacing and is useful in detecting defects such as dislocations, interfaces, and strained layers.

Applications:

- Thin film characterization.

- Strain and stress analysis in semiconductor materials.

- Characterization of multilayered and nanostructured materials.

4. X-ray Reflectivity (XRR)

X-ray reflectivity is used to investigate thin films and surfaces. By measuring the intensity of X-rays reflected from the surface of the material, XRR can provide information on thickness, density, and roughness at the atomic scale.

Applications:

- Determining the thickness of thin films.

- Studying surface and interface roughness.

- Assessing material density in thin layers.

5. In-situ XRD

In-situ XRD refers to the analysis of materials while they are undergoing real-time changes in response to external conditions such as temperature, pressure, or mechanical stress. This technique is particularly useful for studying phase transitions, crystallization, and the behavior of materials under different environmental conditions.

Applications:

- Studying phase transitions at elevated temperatures.

- Investigating material stability and degradation over time.

- Real-time analysis of chemical reactions or material processing.

Applications of XRD in Material Characterization

XRD plays a pivotal role in the characterization of a wide range of materials. Some key areas where XRD is frequently employed include:

1. Phase Identification

XRD is commonly used to identify the different phases present in a material. By analyzing the diffraction pattern, which consists of peaks corresponding to specific crystal planes, the phase(s) present can be identified and compared to standard reference databases. This is crucial for materials research, quality control in manufacturing, and ensuring the desired properties in materials.

2. Crystallographic Structure Determination

XRD allows the determination of the crystal structure of a material, which includes information about the arrangement of atoms, interatomic distances, and symmetry. This is especially important in understanding how a material’s properties—such as strength, conductivity, and reactivity—are linked to its internal structure.

3. Particle Size Analysis

The width of the X-ray diffraction peaks can provide information about the size of crystallites in a material. Smaller crystallites tend to produce broader diffraction peaks, and using the Scherrer equation, the average particle size can be estimated.

4. Strain and Stress Analysis

XRD can be used to measure the strain and stress present in materials, particularly in thin films or nanostructured materials. Strain induces shifts in the diffraction peaks, and the magnitude of these shifts can be used to quantify the internal strain and stress.

5. Texture Analysis

Texture refers to the preferred orientation of grains in polycrystalline materials. XRD is essential for characterizing the texture of materials, which significantly influences the material’s mechanical, electrical, and thermal properties. The intensity of diffraction peaks is analyzed to determine the orientation of grains in a sample.

6. Quantitative Phase Analysis

XRD can also be used to determine the relative amounts of different phases in a sample. By comparing the intensities of the diffraction peaks from each phase, quantitative phase analysis can be performed.

Advantages of XRD

- Non-destructive: XRD is a non-invasive technique, meaning that it does not alter the sample during analysis.

- Wide range of applications: XRD can be applied to a variety of materials, including metals, ceramics, polymers, and semiconductors.

- High precision and accuracy: XRD provides detailed and precise information about the crystal structure and phase composition of materials.

- Rapid analysis: XRD can provide fast, real-time analysis of materials, especially in automated systems.

Challenges and Limitations of XRD

While XRD is an invaluable tool, it does have certain limitations:

- Sample preparation: For powder XRD, the sample must be finely powdered, which may not always be possible for certain materials.

- Non-crystalline materials: XRD is most effective for crystalline materials. Amorphous or disordered materials may not produce a clear diffraction pattern.

- Complex data interpretation: In some cases, interpreting the diffraction data, especially for complex or multi-phase systems, can be challenging and may require advanced techniques or computational analysis.

Conclusion

X-ray diffraction (XRD) is an essential tool for characterizing materials at the atomic and molecular levels. It offers invaluable insights into the crystal structure, phase composition, particle size, texture, and strain of a material. With its versatility and wide range of applications, XRD remains a cornerstone technique in material science, enabling researchers and engineers to develop new materials with tailored properties for various industrial, technological, and scientific applications.

As material characterization becomes more important in emerging fields like nanotechnology, renewable energy, and advanced manufacturing, XRD will continue to play a pivotal role in shaping the future of material science.