The morphology of materials refers to the physical form or structure of a material at various scales. It encompasses the arrangement, shape, size, and distribution of its components, ranging from the atomic to macroscopic levels. The morphology of materials plays a crucial role in determining their properties, behavior, and performance in different applications. Understanding material morphology is essential for the development of new materials with tailored properties to meet specific industrial and scientific needs.

In this blog, we will delve into the concept of material morphology, its various types, and its physical significance in influencing the material’s mechanical, thermal, electrical, and optical properties.

What is Material Morphology?

The morphology of a material refers to its structure and form, which includes both the arrangement of its constituent particles (atoms, molecules, or ions) and the larger-scale features like grains, phases, and textures. It describes the shape, size, and orientation of these elements, which ultimately dictate the material’s behavior under different conditions. This structural arrangement affects the material’s physical properties, such as strength, ductility, conductivity, and more.

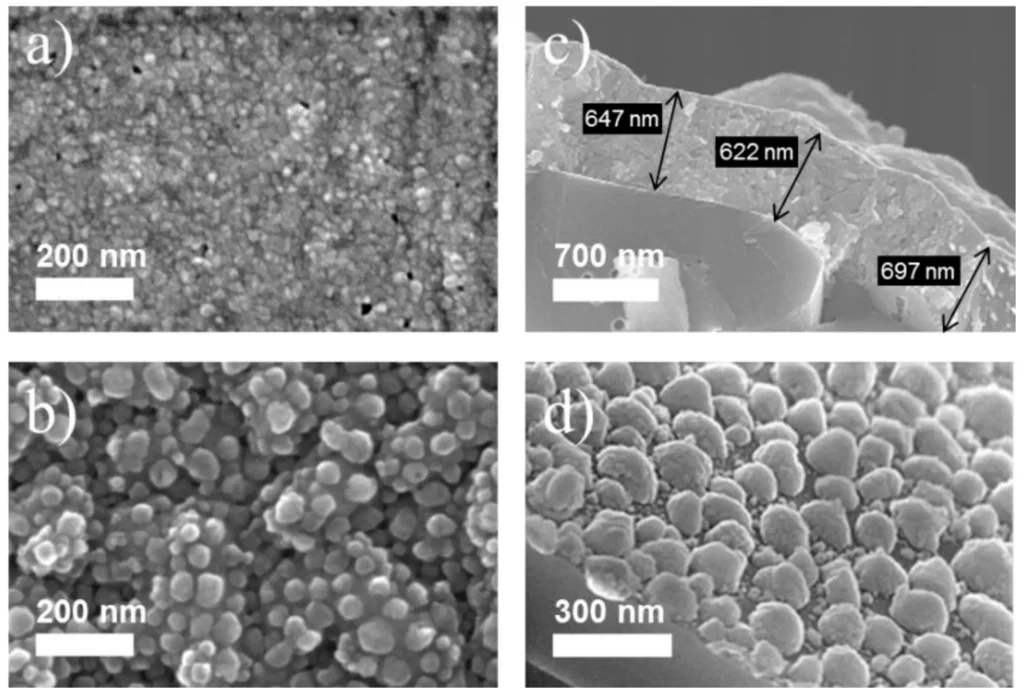

The morphology of materials can be observed through different methods such as microscopy (electron microscopy, atomic force microscopy, etc.), X-ray diffraction, and other imaging techniques that allow researchers to understand the material’s internal structure.

Types of Material Morphology

Material morphology can be broadly categorized into several types based on the scale of observation and the nature of the material’s components. Below are some of the main types of material morphology:

1. Atomic and Molecular Morphology

At the atomic and molecular level, the morphology of materials refers to the arrangement of atoms, ions, or molecules within the material. This level of morphology is essential in determining the chemical properties, bonding types, and the overall crystalline or amorphous structure.

- Crystalline materials: These materials have a highly ordered atomic arrangement, where the atoms repeat in a regular pattern. The morphology of a crystalline material is defined by its crystal lattice, which influences properties like hardness, transparency, and conductivity. Examples of crystalline materials include metals, ceramics, and semiconductors.

- Amorphous materials: These materials lack a long-range ordered structure and have a random arrangement of atoms or molecules. Examples include glass, polymers, and gels. Amorphous materials often exhibit different mechanical properties, such as more flexibility or lower hardness than crystalline materials.

2. Microstructural Morphology

At the microstructural level, the morphology refers to the arrangement and interaction of smaller features within the material, such as grains, phases, and boundaries. This level provides insight into the material’s mechanical properties, such as strength, toughness, and ductility.

- Grain structure: In polycrystalline materials, such as metals, the grains are individual crystalline regions with distinct orientations. The grain size can have a significant effect on the material’s mechanical properties. Smaller grains tend to improve strength by restricting the movement of dislocations.

- Phase structure: Materials may consist of different phases (solid, liquid, gas) or various solid phases (e.g., alloys with different phases like martensite and austenite). The phase composition and its distribution within the material play a major role in determining its overall properties.

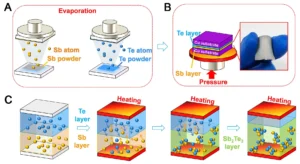

3. Nanostructural Morphology

Nanostructural morphology refers to materials that have structures at the nanoscale, typically less than 100 nanometers in size. Nanomaterials can exhibit unique physical and chemical properties due to their size and high surface area. These materials can have various shapes, including nanoparticles, nanotubes, nanowires, and thin films.

- Nanoparticles: These have a high surface-to-volume ratio, which can influence properties like reactivity, strength, and optical behavior. For example, gold nanoparticles exhibit different optical properties than bulk gold due to surface plasmon resonance.

- Nanowires and Nanotubes: These materials are characterized by their elongated shape and can exhibit enhanced electrical, thermal, or mechanical properties, making them suitable for applications in electronics, energy storage, and nanocomposites.

4. Macroscopic Morphology

At the macroscopic level, morphology refers to the large-scale structure of the material that is visible to the naked eye. This type of morphology can be observed through visual inspection or techniques like scanning electron microscopy (SEM).

- Porosity: The presence of pores or voids within the material can significantly affect its mechanical strength, thermal insulation, and electrical conductivity. Materials with controlled porosity, such as foams or aerogels, are used in applications like insulation and lightweight composites.

- Surface roughness and texture: The surface morphology of a material, such as whether it is smooth or rough, can impact properties like friction, adhesion, and wear resistance. For example, materials with rough surfaces may have better grip or higher friction.

Physical Significance of Material Morphology

The morphology of materials influences their physical properties in numerous ways. Here are some key physical aspects that are affected by morphology:

1. Mechanical Properties

The mechanical properties of materials—such as strength, hardness, ductility, and toughness—are heavily influenced by their morphology.

- Grain size: In polycrystalline materials, smaller grain sizes generally result in higher strength, as the grain boundaries act as obstacles to dislocation movement (according to the Hall-Petch relationship).

- Porosity: Materials with higher porosity tend to have lower mechanical strength due to the presence of voids that act as stress concentrators. However, controlled porosity in materials such as foams can lead to lightweight yet strong materials, useful in aerospace and construction.

- Phase distribution: The morphology of phases, such as the distribution of hard and soft phases in a composite material, can enhance properties like wear resistance, flexibility, or impact strength.

2. Thermal Properties

The thermal conductivity of materials is also affected by their morphology. For instance, materials with high porosity often have lower thermal conductivity because air pockets (which are poor heat conductors) reduce heat transfer. Nanomaterials, on the other hand, can have superior thermal properties due to their unique surface and size effects.

3. Electrical and Optical Properties

In materials used for electronic and optical applications, morphology plays a crucial role in determining electrical conductivity and optical behavior.

- Nanostructured materials: At the nanoscale, the density of states and quantum effects can significantly enhance the electrical and optical properties of materials. For instance, quantum dots or nanowires can exhibit unique electronic and photonic behavior that is not present in bulk materials.

- Surface morphology: The texture of a material’s surface can influence its optical properties, such as light reflection, refraction, and transmission. For example, surface roughness on solar panels can increase light absorption, improving energy efficiency.

4. Chemical Reactivity

The surface area and porosity of materials can affect their chemical reactivity. Nanomaterials, with their large surface-to-volume ratio, often exhibit enhanced chemical reactivity compared to their bulk counterparts. This makes them useful in catalysis, sensing, and drug delivery applications.

Applications of Morphological Control in Material Design

Understanding and controlling material morphology is key in designing advanced materials with specific properties for targeted applications. Some examples include:

- Composites: The morphology of the reinforcing phase (e.g., fibers, nanoparticles) and the matrix material plays a key role in the final mechanical, thermal, and electrical performance of composites used in aerospace, automotive, and construction.

- Nanotechnology: Nanomaterials, with their unique morphology at the nanoscale, are used in applications ranging from drug delivery systems to next-generation batteries, photovoltaics, and sensors.

- Additive manufacturing (3D printing): The ability to control the morphology of materials in 3D printing enables the production of complex geometries with tailored properties, such as lightweight but strong components or structures with specific porosity for filtration.

Conclusion

The morphology of materials is a critical factor in determining their behavior and performance in a wide range of applications. Whether at the atomic, microstructural, or macroscopic level, the arrangement and structure of material components influence properties such as strength, conductivity, reactivity, and optical characteristics. By understanding and manipulating material morphology, researchers and engineers can design advanced materials for use in various industries, from electronics to energy storage, construction, and biomedicine. Thus, the study of material morphology continues to be an essential area of research for material science and engineering.