In the realm of physics and material science, the study of mechanical properties of materials is crucial for understanding how they behave under various stresses and strains. One important property that helps in comprehending the deformation of materials under shear stress is the modulus of rigidity, often denoted by the symbol G.

What is Modulus of Rigidity?

Modulus of rigidity, also known as shear modulus, is a measure of a material’s resistance to deformation under shear stress. When a force is applied parallel to the surface of a material, causing its shape to change without altering its volume, shear stress occurs. The modulus of rigidity quantifies the ratio of shear stress to the shear strain within the material.

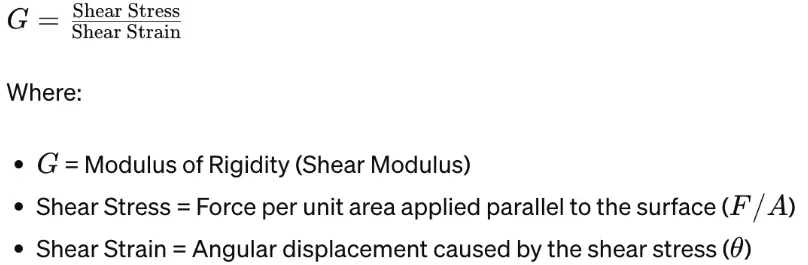

Formula and Calculation

Mathematically, the modulus of rigidity is expressed as:

Understanding Shear Stress and Shear Strain

- Shear Stress: Shear stress refers to the force applied per unit area parallel to the surface of a material. It’s calculated by dividing the force applied (F) by the cross-sectional area (A) of the material experiencing the force.

- Shear Strain: Shear strain describes the deformation caused by the shear stress. It’s measured in radians and represents the change in angle between two lines originally perpendicular to each other within the material.

Importance and Applications:

- Material Selection: Understanding the modulus of rigidity helps engineers select appropriate materials for specific applications. For instance, materials with high shear modulus are preferred for applications requiring high rigidity and resistance to deformation, such as in building construction or manufacturing of structural components.

- Elasticity Prediction: Modulus of rigidity is essential in predicting the elastic behaviour of materials. Materials with high shear modulus exhibit less deformation under shear stress, making them suitable for applications where minimal deformation is desired, such as in precision engineering.

- Mechanical Design: Engineers use the modulus of rigidity to design components subjected to shear stress accurately. For example, in designing torsion bars for automotive suspensions, understanding the shear modulus helps in selecting materials that can withstand the expected loads without failure.

- Material Testing: Experimental determination of the modulus of rigidity involves subjecting a sample of the material to controlled shear stress and measuring the resulting shear strain. This testing helps in characterising the mechanical properties of materials and assessing their suitability for various applications.

Modulus of Rigidity and Young's Modulus

It’s worth noting the relationship between modulus of rigidity (G) and Young’s modulus (E). While Young’s modulus quantifies a material’s resistance to axial or tensile stress, the modulus of rigidity measures its resistance to shear stress. These two moduli are related by the equation:

E = 2G (1+ν)

Where:

- E = Young’s Modulus

ν = Poisson’s ratio (a measure of the material’s lateral contraction under axial stress)

Conclusion:

The modulus of rigidity is a fundamental property that characterises a material’s response to shear stress. Understanding this property is essential for engineers and scientists working in various fields, including mechanical engineering, material science, and structural design. By quantifying a material’s resistance to deformation under shear stress, the modulus of rigidity plays a crucial role in material selection, mechanical design, and predicting material behavior under different loading conditions.